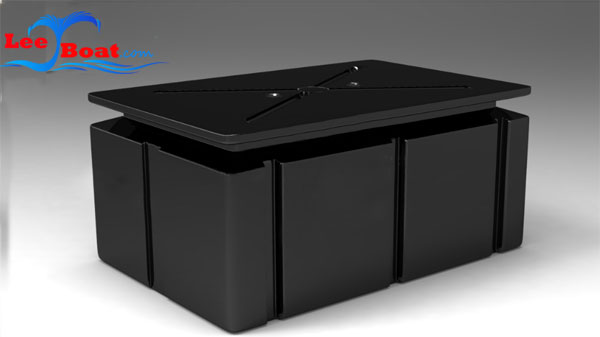

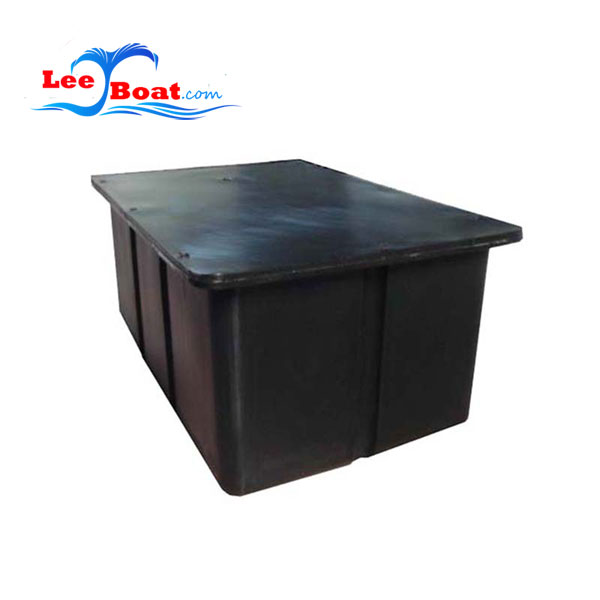

Rotational Rotomolding plastic pontoon for docks

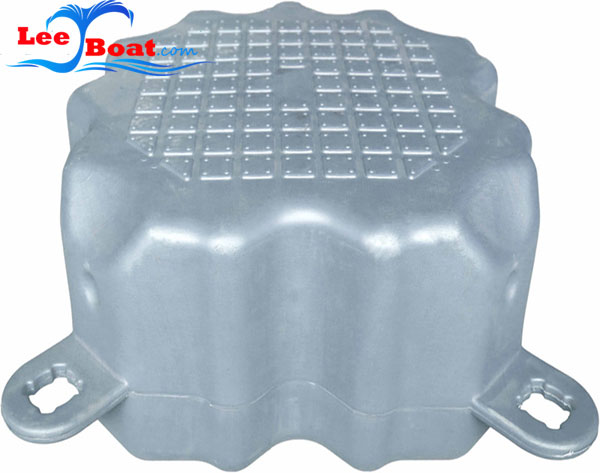

Water Boat Dock System Float Drum

Rotational Molding, also called rotomolding or rotocast, is a

thermoplastic process for producing hollow parts by placing powdered

resin into a hollow mold and then rotating that mold bi-axially in an

oven until the resin melts and coats the inside of the mold.The mold is

then cooled and the part is removed from the mold. Rotational molding

can produce small to large, simple to complex parts.Such as road

barrier, kayak, buoy .etc are made by rotational molding

process.We can find rotomolded products everywhere in our life.

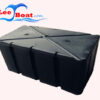

PE Plastic Badge Rotomold Foam Filled Floating Dock

1.rotomolding PE shell,seamless

2.one piece EPS foam filled inside

3.UV resist,weather proof

4.Strong, long life

5.OEM is available

Rotational moulding or Roto Molding which is a high temperature, low

volume, low pressure thermoplastic forming process .It mainly suite for

producing hollow, one piece parts such as large oil or chemical tanks,

kayaks, point of purchase displays, frames, cases, furniture,carts,

dispensers, park equipment. The material can be UV resistant which can

ensure the outdoor use of your products .

Material: PE+EPS inside

Life span: above 10 years

Temperature Test: can work at -40 C to 60 C

- Material: imported PE for the sell, expanded polystyrene(EPS) foam filled to make sure the maximum buoyancy.

- Maintenance free: Wouldn’t rust, splinter, peel or corrode.

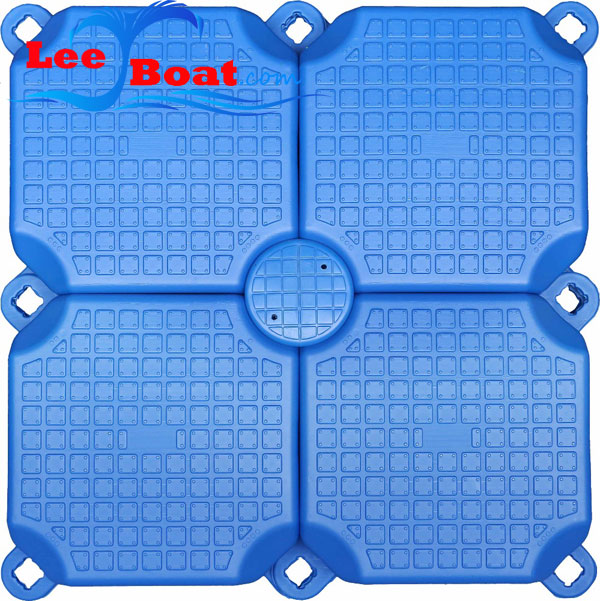

- Usage: Widely used in marina (dock,jetty, wharf, quay) building.

- Environmental friendly.

- Any color is customized

Application

The

navigation buoy is capable of supporting substantial loads.So that it

has a wide application areas: coastal harbor, inland river, rocks,

beach, islet, reef and bank etc.

We

are professional to do rotational molded buoys. And we are dedicated to

build long term cooperation relationship with our clients.

We have competitive price with excellent quality, and good faith management.

We

use imported food PE raw materials, light weight and have big buoyancy.

Because of it’s higher corrosive resistance, anti-aging , it’s safe and

durable.

Good quality

It’s anti-UV , good flexibility,and excellent impact resistance, no crack.Also it’s environmentally friendly.

Customized

Size, color or logo can be customized according to customer requirement.

Reasonable price

You

can save much more expenses and time on preservation, replacement and

repair. Low mould costs. And the working life is three times of steel

pontoon life.